Insights

Application and Prospects of Industrial-Grade Polyvinyl Acetate (PVAC) in BMC Pultrusion

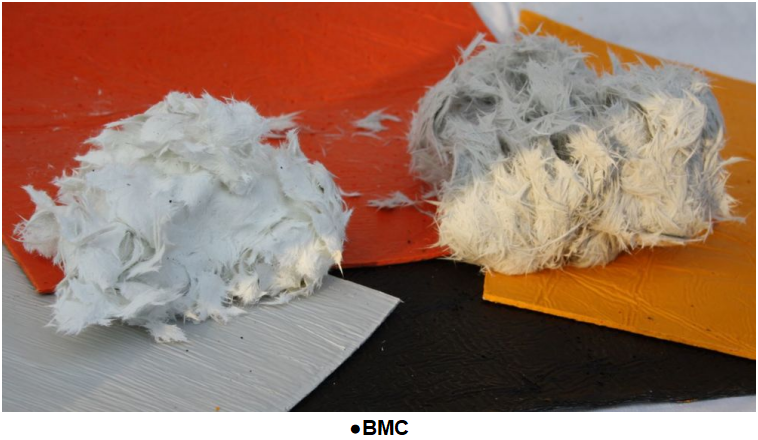

BMC (Bulk Molding Compound) is a composite material composed of unsaturated polyester resin, glass fibers, fillers, and additives. It is known for its high strength, corrosion resistance, and excellent insulation properties, making it widely used in automotive, electronics, and construction industries.

As an auxiliary resin, PVAc enhances the interfacial adhesion between the resin, fibers, and fillers in BMC systems, improving the overall strength of the composite. Its excellent flowability ensures better fiber wetting during the pultrusion process, reducing defects. PVAc's thermal stability allows it to withstand high temperatures in pultrusion, minimizing resin decomposition or bubble formation. Additionally, PVAc increases the toughness of BMC materials, reducing the risk of brittle fractures. Its compatibility with various resins and fibers improves the interfacial bonding of BMC components, enhancing overall material performance. As an industrially producible resin, PVAc is cost-effective, non-toxic, and environmentally friendly, aligning with modern industrial sustainability requirements.

PVAc has been successfully applied in BMC pultrusion for automotive parts, electrical insulation materials, and more. With the growing demand for composite materials, industrial-grade PVAc demonstrates significant advantages in BMC pultrusion, effectively enhancing material performance and meeting diverse industrial application needs.

Discover our PVAC products here. Explore how it can optimize your production today!

RELATED NEWS

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Audrey Yang

Phone: (+86) 17686622986

E-mail: audreyyang.nuoda@gmail.com

Whatsapp:

Add: No. 246 Xingfu Middle Road, Zhifu District, Yantai, Shandong Province, China